Industrial Zone,Yutian,Hebei,China 17/F,Zhida Group,North Road,Yutian,Hebei,China

Tel/Fax:+86-315-6365786

M/Wechat/Whatsapp:+86 15230576812

Mail:info@laizhangjx.com

Web:www.laizhangjx.com

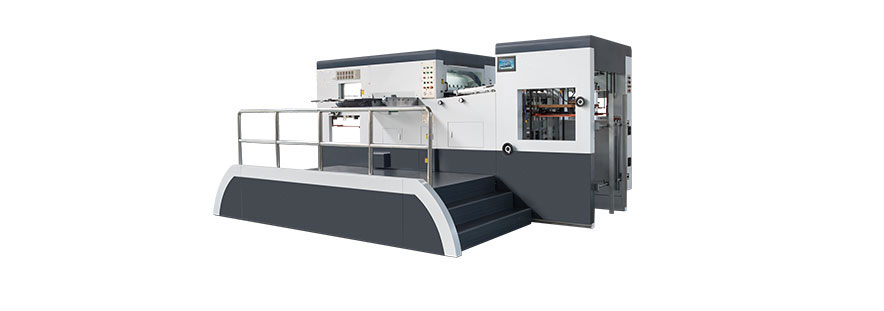

MY1080RⅢ Automatic Deep Press Die-Cutting Machine

Main Features

1. The main wallboard is 120 mm of thickness, and up to 600 tons of pressure in order to meet the process requirement for deep press.

2. For card paper, working speed is up to 7000 times/hour, die-cutting precision is less than ±0.1 mm. For corrugated paper, working speed is up to 6000 times/hour, die-cutting precision is less than ±0.15 mm, and die-cutting thickness is less than 5 mm.

3. Die cutting upper platform adds 12 heating temperature zones. Temperature of temperature zone can be individually controlled to make heating temperature uniform, which is used for deep press, hot pressing of unevenness and hot pressing mark.

4. Time-lapse pressure setting deep press function, the pressing time can be set freely on the touch screen, making the deep press firmer and better effect.

5. Adopt PCL computer program control, and install a man-machine interface display screen in both of operating surface and paper receiving surface to constantly monitor the machine running state, and make a dynamic monitoring of the input and output points and various fault of computer program controller. Installation of the man-machine interface display screen in both surfaces is very convenient for trouble shooting and operation .

6. Front lay positioning adopts four electric front guide mechanisms, and installs four photoelectric detection switches.

7. Lateral positioning adopts integration design for pull lay and push lay, and can be adjusted to swap pull and push position so as to adapt to the die cutting of card paper and corrugated paper, and has a photoelectric detection for position accuracy of paper.

8. Hot-pressing honeycomb plate, cutting die chase and die cutting steel plate, which are positioned by pneumatic lock plate, are accurate precision and convenient operation.

9. Hot-pressing honeycomb plate and die cutting chase can replace each other, so as to realize the transformation of hot press and die cutting functions.

10. Electric digital display is used for the lifting pressure so that pressure size, position and pressure precision die of cutting platform are easy to be adjusted in the man-machine interface display screen.

11. British Renold’s high-precision and high-strength gripper bar rotation chain, via the prestretching for one-to-one matching, ensures that each group of gripper bar chain is accurate.

12. High-strength aluminum alloy gripper bar makes gripper smooth to effectively prevent the vibration of gripper bar.

13. Front-back localization of gripper bar adds an adjustable device, and the positioning precision of gripper bar can be compensated for main chain or parts wear error by making small adjustments.

14. Five critical components bearing die cutting pressure, including left and right die wall, upper platform, moving platform and base frame, are from high temperature integral casting of pressure-proof high-strength ductile iron, and experience a long-time stress release and tempering, and aging treatment, to ensure the permanent non-deformation and stable pressure in the high pressure die cutting.

15. Circulating oil cooling system can ensure the internal joint lubrication effect of main drive. Forced self-lubrication system ensures the normal internal oil supply of main drive, and avoids automatic stop without oil. Timing lubrication system automatically controls the timing and quantitative oil lubrication of all lubricating points.

Main Specification

|

Model |

MY1080RⅢ |

|

Max. feed size |

1080×780mm |

|

Min. feed size |

400×370mm |

|

Highest working speed |

7000 times/hour (cardpaper) / 6000 times/hour (corrugated paper) |

|

Max. working pressure |

600T |

|

Die cutting precision |

±0.1mm |

|

Min. gripper edge size |

6mm |

|

Max. height of feed pile |

1500mm |

|

Max. height of receiving pile |

1500mm |

|

Paper thickness |

Paper processing thickness (card paper) 100-2000g/m² paper ≤ 4 mm |

|

Total weight |

21T |

|

Number of heating zone |

12 zone |

|

Temperature of heating plate |

40-190℃ |

|

Total power |

29.5kw+24kw(heating) |

|

External dimension |

5450×4200×2300mm |