Industrial Zone,Yutian,Hebei,China 17/F,Zhida Group,North Road,Yutian,Hebei,China

Tel/Fax:+86-315-6365786

M/Wechat/Whatsapp:+86 18131736821

Mail:info@laizhangjx.com

Web:www.laizhangjx.com

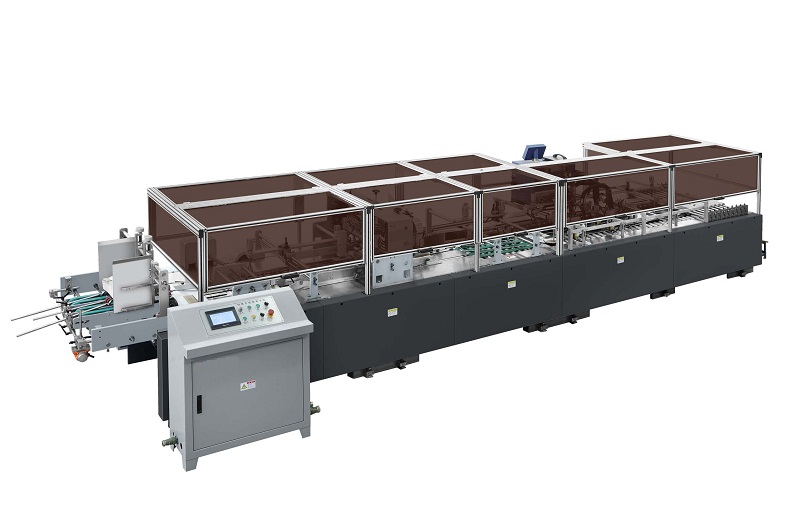

LZ-350/1040C Automatic Paper Bag Making Machine

LZ-350/1040C Automatic Paper Bag Making Machine

Introduction:

LZ-350/1040C automatic paper bag bottom card inserting machine process the paper bags without bottom glue as raw material, of automatic paper bags conveyance supply, a combination of hooks and paper separation suction nozzle to open the bottom, the compaction to achieve a definite shape, then suction the cardboard into the bag bottom, pasted by the hot melt glue system(water glue is optional), finally compacted outputs.

It’s simple to operate, high performing, and cost-effective. Short time of changing different bag sizes, saving labor, producing more bags with fewer man-hours. The machine LZ-350/1040C can be worked together with LZ-350/1040 automatic paper bag machine by connecting directly.

Technical Parameters

|

Paper Bag Width |

180-350mm (7.08-13.78 inch) |

|

Paper Tube Length |

290-600mm (11.42-23.62 inch) |

|

Paper Bag Bottom/Gusset |

70-150mm (2.75-5.90 inch) |

|

Paper Sheet Width |

530-1040mm (20.86-40.94 inch) |

|

Paper Sheet Length |

290-600mm (11.42-23.62 inc) |

Paper Types/Paper Weight |

A. White/Brown Kraft Paper: 80-200g/m²

B. Art Paper + Laminated PP Film: 100-200g/m²

C. White Cardboard: 180-250g/m²(After die cutting process )

D. Grey Paperboard + Laminated PP Film: 150-250g/m²

(After die cutting process ) |

|

Working Speed |

40-70pieces/min. |

|

Glue Type |

Water Glue(Optional hot melt glue system to paste the bag tube) |

|

Total Power |

10KW |

|

Machine Weight |

10000KGS |

|

Machine Dimension(L*W*H) |

14000*1800*1700mm |