Industrial Zone,Yutian,Hebei,China 17/F,Zhida Group,North Road,Yutian,Hebei,China

Tel/Fax:+86-315-6365786

M/Wechat/Whatsapp:+86 15230576812

Mail:info@laizhangjx.com

Web:www.laizhangjx.com

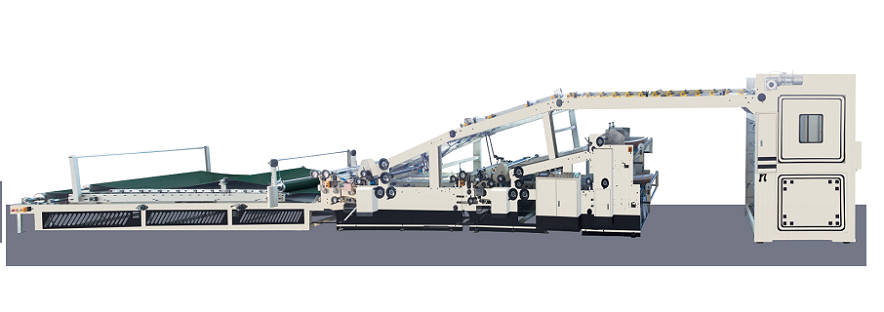

ZL-1450/1650AUTOMATIC THREE-IN-ONE FLUTE LAMINATING MACHINE

Main Features

1. LITHO FEEDER FOR CARDBOARD:

Stream feeding suction head.

Four sets of forwarding and two sets of up&down suckers to ensure smooth feeding of substrate boards.

Emergency stop control for double sheet detection, missed sheets, paper jam or misaligned sheets.

2. MIDDLE AND BOT TOM CORRUGATED BPOARD FEEDERS:

Corrugated boards to be fed by either feeder or both feeders.Single piece of board delivery, strong suctionn form air blower.

Equipped with 14 sets of suction belts(7in each feeder) to ensure strong grasp and smooth feeding.

3.PAPER DELIVERY BRIDGE:

Side spring leaves to ensure accurate sidelay paperdirection and smooth delivery.

Alignment machinanism includes twenty sets of pushing ,claws(8 sets in front and 12 sets at backside). ,which are drinen smoothly by chains on both sides to ensure and bottom boards are laminating precisely.

4. GLUING AND LAMINATING SYSTEMS:

Front gluing and laminating system to ensure lamination ofA+A. A+B. A+E, B+A. B+B. B+E. E+A. E+B. E+E, free combinationof different flutes, or single corrugated board, Back gluing and laminating system to ensure lamination between printed or film laminatesupper paper with front laminated corrugated boards,Regular running speed is 0- 80 sheets per minute subject to paper size and paperquality. There are 4 roliers in one gluing system including one gluing roller, one metering roller, one pressure roller and one water roller.Metering roller can control the thickness of the glue, while the guling roller pasts glue on bottom corrugated boards and the pressureroller grasps the laminated sheets and delivers forward.

|

Model |

ZL-1450

|

|

Max. Paper Size(W×L)

|

1450x1100mm

|

|

Min. Paper Size(W×L)

|

400mmx400mm

|

|

Thickness of Upper Paper

|

150~800g/㎡

|

|

Thickness of Bottom Paper

|

0.5~10mm

|

|

Machine Speed

|

0~100/min

|

|

Accuracy

|

±2.5mm/㎡

|

|

Machine Space

|

15336Lx2450Wx2600H

|

|

Power

|

380V28HP

|

|

Weights

|

8800KG

|

|

Model |

ZL-1650

|

|

Max. Paper Size(W×L)

|

1650x1100mm

|

|

Min. Paper Size(W×L)

|

450mmx420mm

|

|

Thickness of Upper Paper

|

150~800g/㎡

|

|

Thickness of Bottom Paper

|

0.5~10mm

|

|

Machine Speed

|

0~80/min

|

|

Accuracy

|

±2.5mm/㎡

|

|

Machine Space

|

15336Lx2650Wx2600H

|

|

Power

|

380V30HP

|

|

Weights

|

9800KG

|